Qingdao Victory Plastics Co., Ltd.

được chứng nhận

ISO 9001, UL, SGS

24 + Năm

kinh nghiệm

Địa điểm

Thanh Đảo, Trung Quốc

Nếu bạn cần sản phẩm và dịch vụ của chúng tôi, vui lòng cung cấp các thông tin sau đây để chúng tôi có thể phục vụ bạn tốt hơn:

1. Bản vẽ và mẫu sản phẩm.

2. Lĩnh vực mà sản phẩm thuộc về (điện gia dụng, ô tô, điện tử, v.v.).

3. Số lượng (hàng năm) của sản phẩm hoặc số lượng của mỗi lô.

4. Khu vực sử dụng khuôn.

5. Các yêu cầu đặc biệt khác.

6. Sản phẩm mới hay sản phẩm hiện tại đã ổn định?

Chúng tôi sẽ xem xét thông tin bạn cung cấp và gửi cho bạn một báo giá sớm nhất có thể trong vòng 24 giờ.

8 kỹ sư dự án, 30 nhà thiết kế có kinh nghiệm tốt, và 8 kỹ sư quy trình có nhiều kinh nghiệm trong mô phỏng CAE với Autoform hoặc Danyform.

Phần mềm 3D CAD/CAM mới nhất để thiết kế và xây dựng tất cả khuôn và công cụ của chúng tôi.

Cải thiện hệ thống quản lý tiêu chuẩn khuôn của khách hàng để đảm bảo thiết kế và sản xuất khuôn đáp ứng được yêu cầu của khách hàng của chúng tôi.

Chúng tôi có nhiều đội dự án tại Hoa Kỳ, Mexico và châu Âu để hỗ trợ quản lý dự án và dịch vụ sau bán hàng.

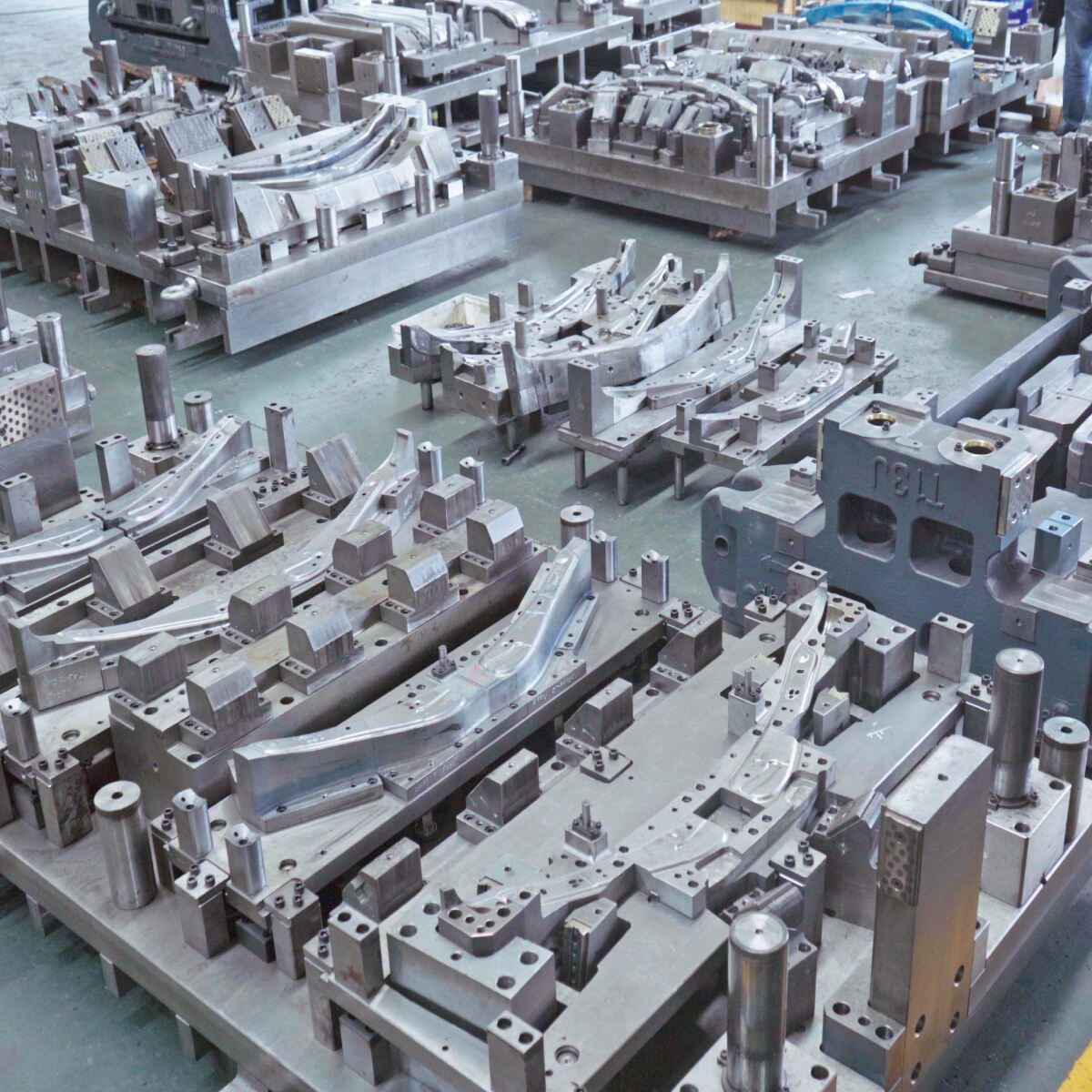

Chất lượng cao

Độ thẩm mỹ, độ chính xác của kích thước, sự tin cậy và năng suất của các bộ phận nhựa và kim loại phụ thuộc vào thiết kế và chất lượng của khuôn. Đặc điểm của khuôn như một tài nguyên sản xuất cũng rất quan trọng, đơn giản trong việc bảo trì thường xuyên.

Hiệu quả cao

Chi phí đặt hàng khuôn chất lượng cao được bù đắp hơn nhiều trong suốt vòng đời của chúng: thời gian ngừng hoạt động của thiết bị được tối thiểu hóa, năng lượng và vốn không bị lãng phí cho sửa chữa và hiệu chỉnh, và sản phẩm đúc được định vị ở mức tốt hơn so với đối thủ cạnh tranh.

SHQD cung cấp cho khách hàng của chúng tôi những kết quả tuyệt vời sẽ giảm chi phí nhân công thông qua dịch vụ gia công kim loại tấm & sản xuất khuôn tiêm được hỗ trợ bởi công nghệ hiện đại. Sản phẩm của chúng tôi giúp đạt được kết quả lý tưởng nhất sau quá trình tạo hình bằng cách tối thiểu hóa sự lãng phí vật liệu!

Chúng tôi cung cấp dịch vụ trọn gói từ thiết kế khuôn, sản xuất đến ép nhựa và sản xuất dập kim loại.

Gửi cho chúng tôi bản phác thảo hoặc mẫu khuôn của bạn

Xác nhận thông số kỹ thuật của các bộ phận

Xác nhận báo cáo phân tích DFM

Xác nhận thiết kế 3D khuôn và xem xét

Mua vật liệu và sản xuất

Kiểm tra thử nghiệm khuôn

Kiểm tra kích thước

Kiểm tra vật liệu

Kiểm tra và phê duyệt chi tiết

Kiểm tra chấp nhận cuối cùng của khuôn

√ Việc phát triển khuôn được hướng dẫn bởi kế hoạch tổng thể và theo dõi dự án.

√ Mỗi giai đoạn được theo dõi bởi kỹ sư dự án theo lịch trình từ khi bắt đầu dự án.

√ Kỹ sư dự án sẽ tổ chức, phối hợp và xử lý bất kỳ vấn đề nào trong trường hợp xảy ra sự cố để đảm bảo hiệu quả ngày hoàn thành của mỗi khuôn.