Qingdao Victory Plastics Co., Ltd.

certificat

ISO 9001, UL, SGS

24 + Ani

experiență

Locație

Qingdao, China

Dacă aveți nevoie de produsele și serviciile noastre, vă rugăm să ne furnizați următoarele informații, astfel încât să putem să vă oferim o asistență mai bună:

1. Desene și probe ale produselor.

2. Domeniul căruia aparține produsul (electrocasnice, automotive, electronică, etc.).

3. Cantitatea (anuală) a produsului sau cantitatea fiecărei serii.

4. Zona unde se utilizează forma.

5. Orice alte cerințe speciale

6. Produse noi sau produse existente mature?

Vom examina informațiile pe care le oferiți și vom furniza o cotare cât mai curând posibil în curs de 24 de ore.

8 ingineri de proiect, 30 dezaigneri cu experiență și 8 ingineri de proces care au o experiență bogată în simularea CAE cu Autoform sau Danyform.

Ultimul software 3D CAD/CAM pentru a proiecta și construi toate moldurile și instrumentele noastre.

Îmbunătățirea sistemului de gestionare al standardelor clientului pentru a se asigura că proiectarea și fabricarea formei corespunde cerințelor clienților noștri

Avem câteva echipe de proiecte în Statele Unite, Mexic și Europa care să ne ajute în gestionarea proiectelor și serviciile după vânzare.

Calitate ridicată

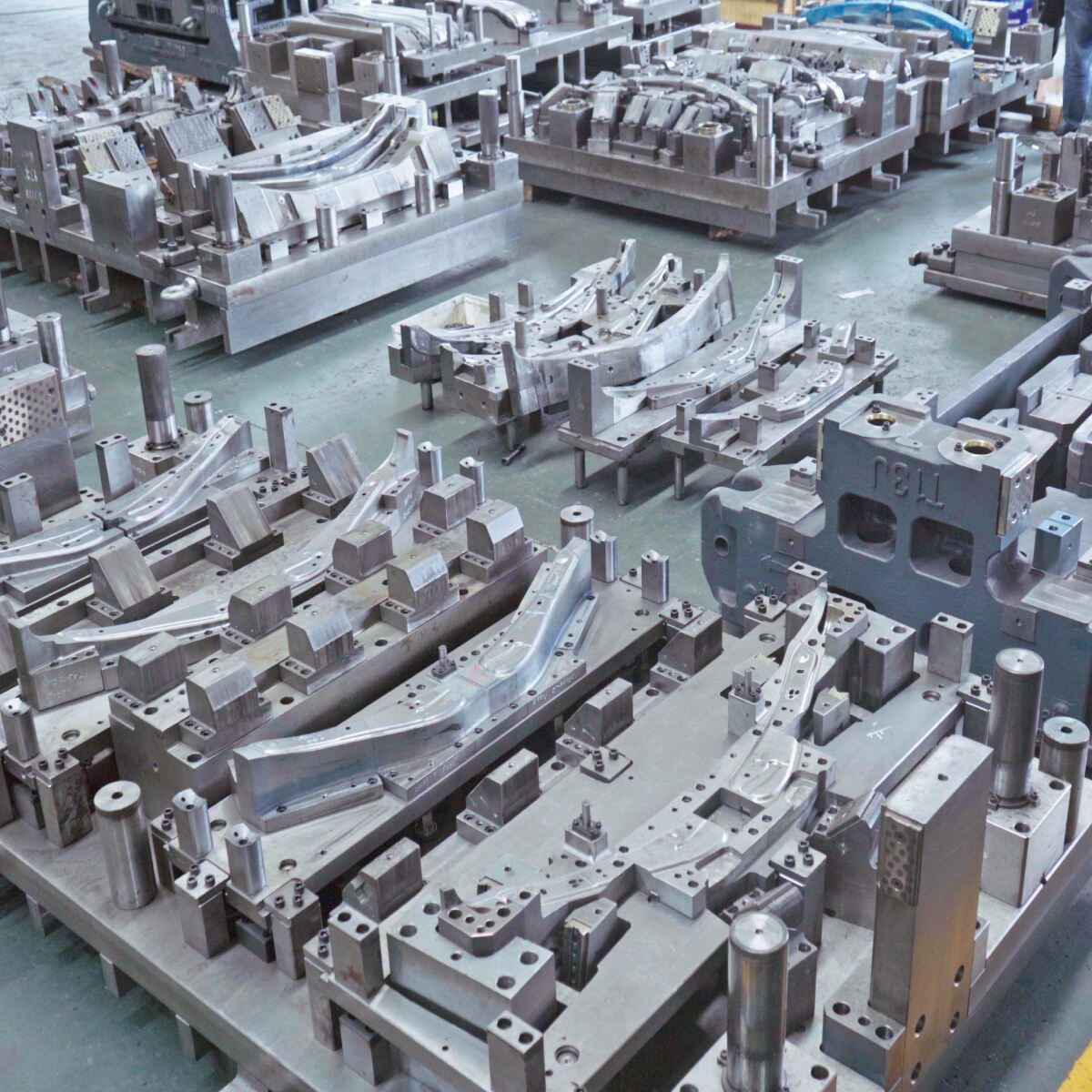

Aparanța, precizia dimensiunilor, fiabilitatea și productivitatea pieselor plastice și metalice depind de proiectarea și calitatea forme. Caracteristicile forme ca resursă de producție sunt de asemenea importante, simplificarea întreținerii rutine.

Eficiență ridicată

Costul comandării de forme de înaltă calitate este compensat de mult timp de viață: minimizarea timpului de funcționare a echipamentelor, energia și fondurile nu sunt cheltuite pentru reparații și depanări, iar produsele de casting sunt poziționate la un nivel mai bun decât concurenții.

SHQD oferă clienților noștri rezultate excelente care vor reduce costurile de muncă prin serviciile noastre de formare metalică pe foaie și producere de forme prin injectare, sprijinite de tehnologie modernă. Produsele noastre ne permit să obținem cel mai ideal rezultat după procesul de formare prin minimizarea pierderii de material!

Ofertăm un serviciu complet, de la proiectarea și fabricarea formei până la formarea prin injectare și producția de impragmat.

Trimiteți-ne schița sau eșantionul moldurii

Confirmați specificațiile pieselor

Confirmați raportul de analiză DFM

Confirmați proiectarea 3D a moldurii și examinați-o

Aprovizionare materiale și fabricație

Validare încercări molduri

Inspectia dimensională

inspecția materialelor

Inspeție și aprobare a piesei

Inspeție finală de acceptare a forme

√ Dezvoltarea formei este ghidată de planificarea generală și urmărirea proiectului.

√ Fiecare etapă este urmărită de inginerul de proiect conform programului, începând cu începutul proiectului.

√ Inginerul de proiect va organiza, coordona și va soluționa orice probleme în cazul apariției de abateri, astfel încât data de finalizare a fiecărei forme să poată fi garantată eficient.