Qingdao Victory Plastics Co.,Ltd.

Certified

ISO 9001, UL, SGS

24 + Years

EXPERIENCE

Location

Qingdao, China

Two essential processes, blasting and powder coating, are used to make industrial equipment look good as new so that every user can enjoy the outmost function prowess. These are the indispensable arts that all lead to high output, however they need certain methods for better results. We will read now each process in the details to know, how do they work and why are important.

Mistakes to Avoid When Blast People for Surface Preparation

PreviousManufacturing and repairing projects both have the first step to be done is surface preparation. This important step in the process is meant to remove any rust, grease and other contaminants from the surface which should be coated. Blasting puts forward itself as the best solution in surface preparation because it is fast, effective and complete. It uses compressed air to force abrasive particles into its tip at high speed, in turn removing any dirt present on the surface.

A Look Into the World of Powder Coating

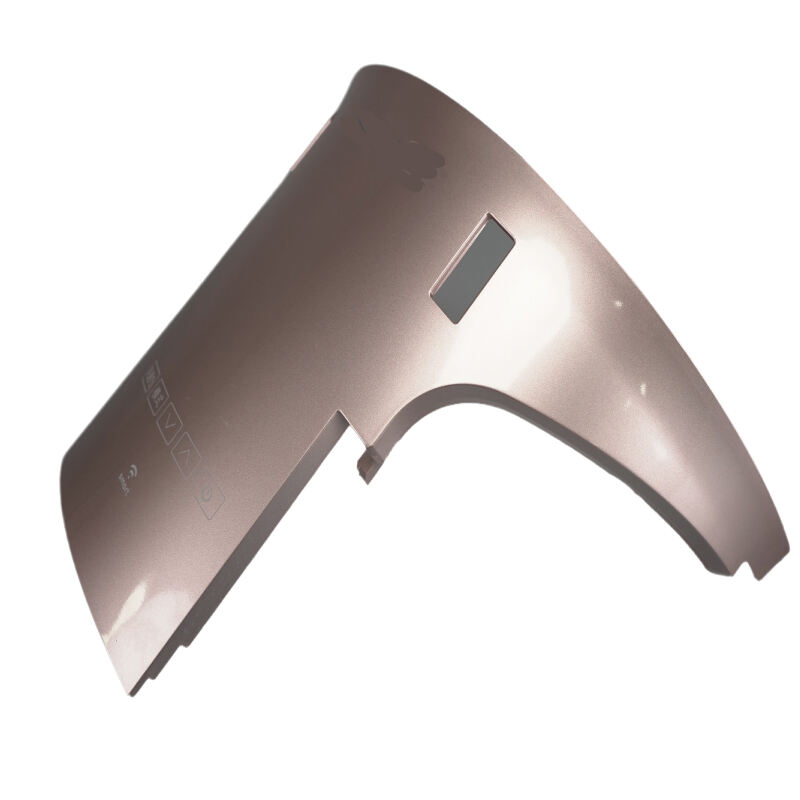

Meanwhile, powder coating is commonly used for coloring heavy equipment or cars. Finely ground, electrically charged particles of resin and pigment to coat the surface Charged particles bond to the surface, which ultimately creates a long-lasting finish that is not only attractive but serves as armor throughout the life of your equipment.

Choosing the right surface preparation and coating technique depends on several factors like- size, shape or existing condition of equipment/surface. For the most massive structures that have high levels of rust, scale or other contaminants blasting is ideal. On the other hand, powder coating is a standout for surfaces that require an aesthetically appealing and durable finish such as in automotive parts or equipment.

The type of material being coated is also an important factor in deciding which method should be used. When you are painting related items like fiberglass, plastic or thin-gauge metal blasting would be the worst one to use as these materials can warp and/or damage. In these cases, surface preparation methods like sanding or chemical stripping may be more appropriate for your application.

As they both deal with dangerous material and equipment such as a blast hood or powder, which only trained professionals should operate. Proper handling and protective measures are a must to prevent any harm during the operation. When working with abrasive particles and coating materials, wear personal protective equipment (e.g., glove,nose mask,mote kun etc.) as suggested by suppliers. Moreover, it is better to do this under a proper ventilation with fresh air supply in order not to inhale particles of the dust or fume.

There are of course many benefits to using blasting and powder coating for industrial machinery. These methods also improve durability, corrosion resistance and help in beautification as well. A good blasting results in a clean perfectly smooth surface, where those skins with impurities that could compromise the quality and operation of equipment;

Powder coat is available in an insanely wide range of colors, and your favorite brand can give you pretty much whatever color matches the equipment or branding. Tough in industrial conditions: Powder coatings famous for their durability and able to withstand corrosion make them ideal for harsh industrial environments. In addition, powder coating brightens up old and tired equipment into brand-new quality accessible things to your eyes once more.

Customize Your Vehicle With Blasting And Powder Coating Services

Aside from the functions of blasting and powder coating in industrial employment, these processes can be used to provide a personal touch or elevate the aesthetic quality of your vehicle - especially if you are an automotive enthusiast who values uniqueness. Effective blasting removes old paint and surface contamination, providing a clean slate on which to apply the plastic coating.

The powder coating capabilities include an impressive range of hues and finishes -- from RAL colors, gloss level (glossy to matte), plus personalized graphics or logos. Moreover, the disruptor-proof qualities of powder coating mean that its refined looks last through all manner of speed bumps and tight corners as well - keeping your ride looking great for many miles to come.

In short, blasting and powder coating is the backbone of surface preparation and painting in numerous industries like industrial, commercial as well automobile. The choice of appropriate method varies depending on the needs and specifications of a particular project, types of surface materials, scale requirements as well and final desired/portrayed results. Maintaining the correct handling processes and safety precautions is key to a safe working environment. In the end, blasting and powder coating have tons of benefits... better durability, less corrosion resistance time as well as an improved look - all which makes them perfect for a wide selection of tasks.

Our supply chain is proven and our purchasing team is professional We are able to reduce your cost of raw materials as well as provide you with injection molding and blasting and powder coating for cost-effective prices Our sales team can assist you in providing high-quality services by considering various aspects including cost quality quantity and transport

blasting and powder coating has a professional laboratory for testing and 40 QC/QA inspectors. Quality inspection is carried out through the raw materials, semi-finished items and final products. As a certified company under the ISO9001, ISO14001 system, and UL standards SHQD has established an excellent quality control and management of the environment that can precisely control the quality of our products and pass rate. We offer our customers high-quality metal and plastic components.

SHQD with over 24 years experience in manufacturing and distributing injection molding, has grown into one of China's largest injection molding companies. We offer OEM/ODM service for blasting and powder coating as well as injection molding. SHQD boasts over 1,000 production equipment and automated production lines. We offer a single-stop service, from design of the tool to mold making, production, assembly and logistics.

SHQD is a professional RD team, 23 project and design engineers, and over 40 patents for blasting and powder coating and injection molding manufacturing. We rely on our research and development efforts to take part in front-end design and to develop innovative technology, products and technologies for prototypes, tests, and marketing. We're committed in providing high-end custom solutions for our customers project.