Qingdao Victory Plastics Co.,Ltd.

Certified

ISO 9001, UL, SGS

24 + Years

EXPERIENCE

Location

Qingdao, China

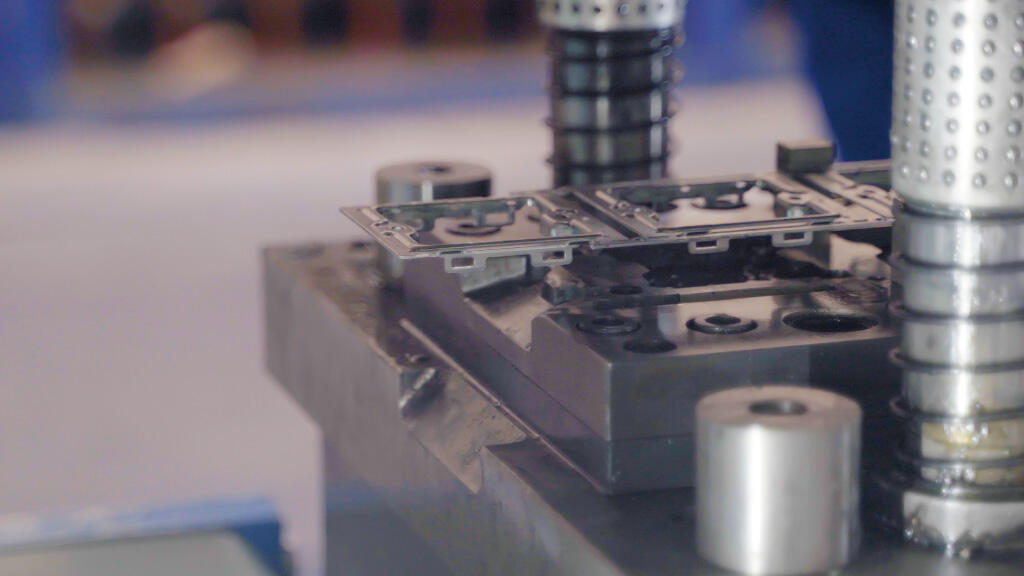

Metal punching is the most efficient and cost-effective method for adding holes and forms in parts. The sheet metal is positioned between a punch and a corresponding die, and when the punch presses downwards into the die, the metal between them is sheared away.

Punch machines can create holes in a wide variety of shapes and sizes, and if a specific shape is needed then a corresponding die can be used. The process of metal punching is extremely fast compared to laser cutting the same holes and forms. Because of this, metal punching is ideal for large runs of parts that contain lots of features.

At SHQD, we have the capability to produce high numbers of quality parts with intricate features and hole patterns. Our machines can produce a variety of holes, countersinks, embossments, louvers, and other formed features. Automated machines can process complex parts with high speed and precision, thereby reducing costs and lead times.