Qingdao Victory Plastics Co.,Ltd.

Certified

ISO 9001, UL, SGS

24 + Years

EXPERIENCE

Location

Qingdao, China

Welding is a key metal joining technique, and at SHQD we have the equipment and skill to deliver high-quality welded parts at a competitive price. We have professional welders and robotic welding, providing spot welding, stud welding, laser welding, and other welding services.

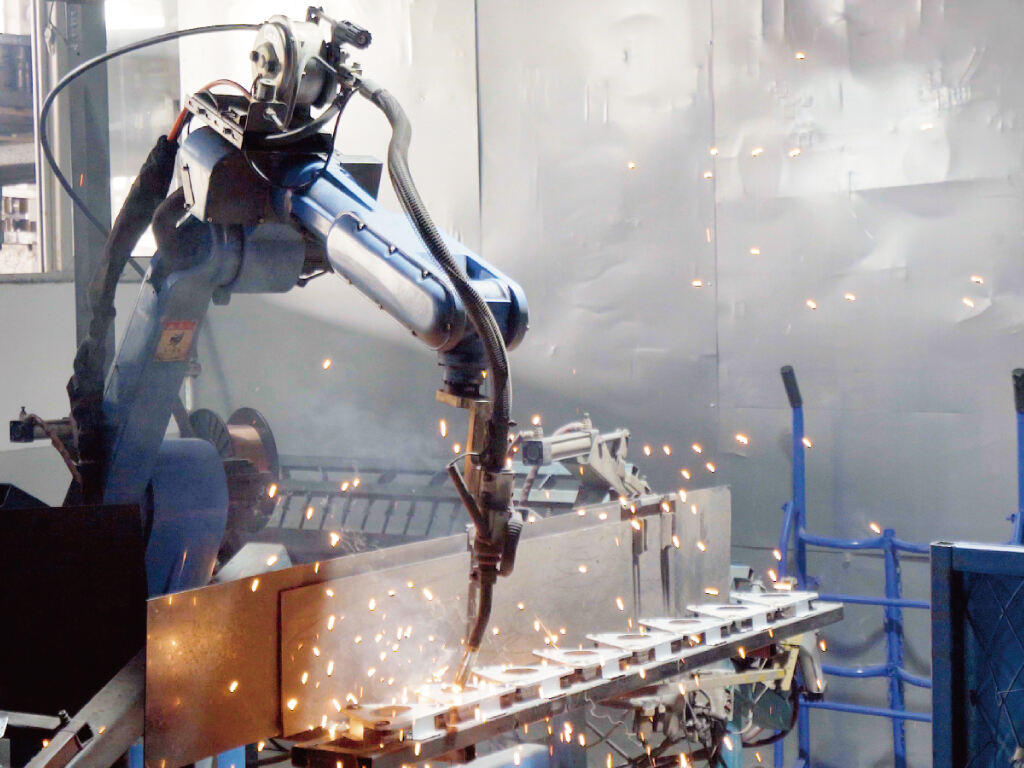

Robotic welding is the process of using an automation system to perform welding tasks. Robots can typically perform any type of welding process and complement rather than replace manual welding. Robots do not need breaks or experience downtime due to shift change.

● Short Cycle Time

● Save Labor Costs and Accuracy

● Consistency Quality control

● High Precision

● High Material Efficiency

● Safety and Low Risk

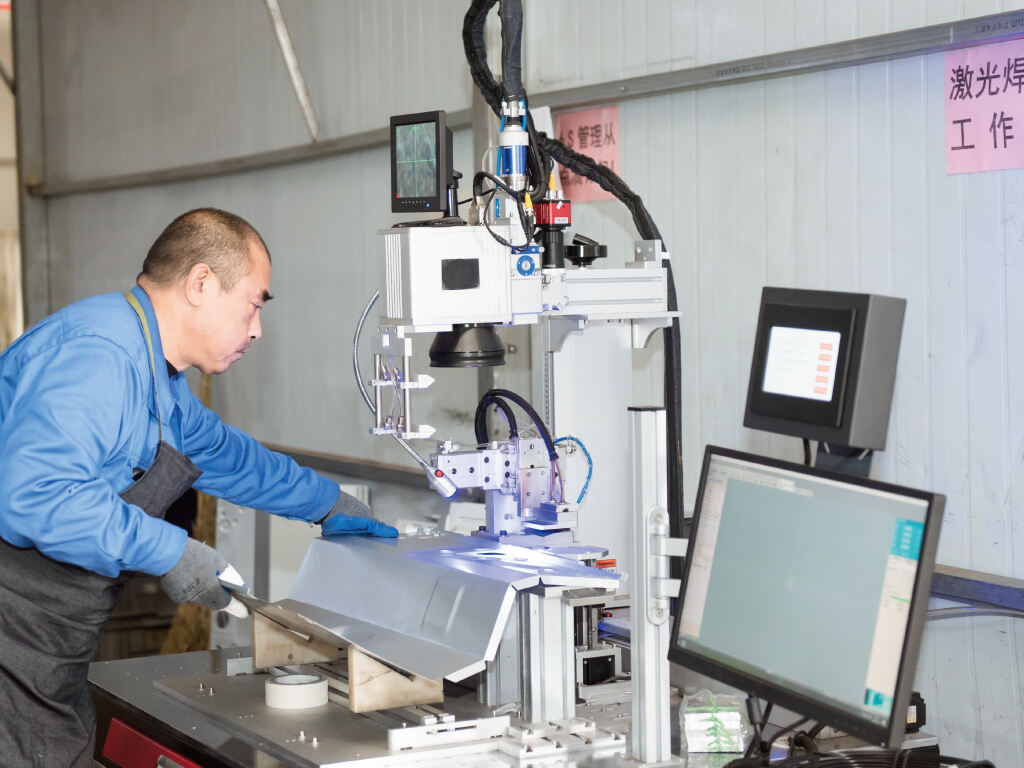

Laser cutting is a precise and surprisingly delicate welding process that uses beam light to join metal parts. The laser beam is produced by a freestanding laser source and directed to a machine-mounted or hand-held collimator “torch”and onto the workpiece. The directed energy beam heats and melts the workpieces (and filler rod if required), and the resulting melt pool fuses the targets, forming a well-integrated weld.

It allows for extremely precise liquefaction with a much smaller heat-affected zone than any other welding method. It is particularly useful for welding materials like aluminum that are difficult to weld by traditional methods.

Spot Welding, also known as Resistance Spot Welding (RSW). Spot Welding does not require filler material, and instead works by using an electrical current to generate heat. This method of welding is best suited for materials with low thermal conductivity that will generate enough conductive metal to bond the metal together.

Because of this, low-carbon steel is one of the most suitable materials for Spot Welding. Spot Welding is best for high production volumes of parts.

Stud welding is a general term used to describe joining a metal stud or similar part to a metal workpiece. Stud Welding covers a range of welding techniques including Drawn Arc Stud Welding, Short Cycle Stud Welding, and Capacitor Discharge Stud Welding, which all produce strong welds.

Stud Welding works by creating an electric arc between a fastener (stud) and the parent material. Stud Welding is a more flexible and economical choice than Spot Welding for a range of welding operations, and is also more versatile in the use of materials.