Qingdao Victory Plastics Co.,Ltd.

Certified

ISO 9001, UL, SGS

24 + Years

EXPERIENCE

Location

Qingdao, China

Sheet metal forming processes are typically performed at room temperature and used for high-volume production. Metal materials are placed on a press, and then powerful pressure is applied through a die to punch, pierce, bend, or stretch the metal material to create the desired parts.

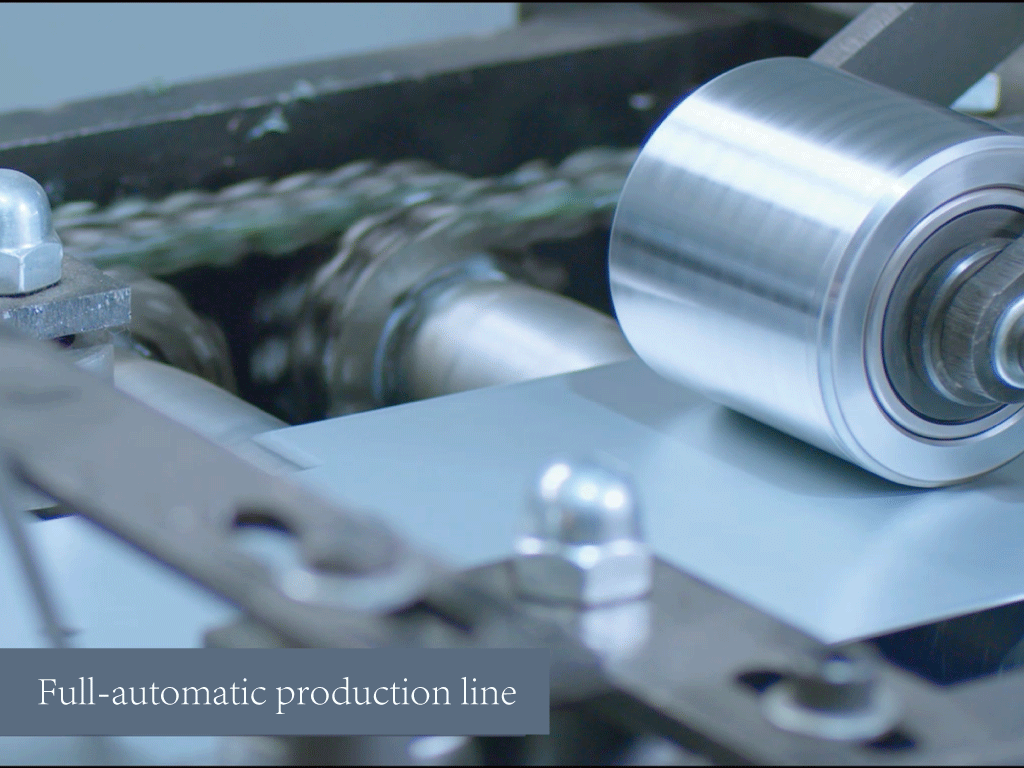

Definition: Roll forming is a continuous process that converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

Feature: The unique aspect of this approach is the use of consecutive forming stations, each of which nudges the metal toward the desired shape. Based on the targeted profile, a computer calculates the optimal placement and shape of the rollers for maximum efficiency and designs the track. The more advanced the desired shape, the more rollers the material goes through. The roll-forming line can bend metal, and form metal into tubes, and beams.

In particular, we have five fully automatic intelligent production lines dedicated to producing refrigerator vertical beams, horizontal beams, and lower beams for Haier refrigerators.

We take pride in the fact that we have independently researched and developed this technology and have our invention patent. Our production lines use the most advanced technology and equipment to ensure that we deliver the optimal balance of quality, delivery, and cost to our customers.

We have developed a state-of-the-art automatic intelligent roll-forming production line that has completely revolutionized the manufacturing process for refrigerator beams.

Our production line has replaced the original eight-step method and has achieved a 100% pass rate for refrigerator beam forming, which is higher than the single-process stamping manufacturing process. Additionally, we have improved the flatness of refrigerator beams from 0.5mm to ≤ 0.3mm, which is a significant improvement from the previous single-punch process.