Qingdao Victory Plastics Co.,Ltd.

-

Certified

ISO 9001, UL, SGS

-

24 + Years

EXPERIENCE

-

Location

Qingdao, China

Qingdao Victory Plastics Co.,Ltd.

Certified

ISO 9001, UL, SGS

24 + Years

EXPERIENCE

Location

Qingdao, China

Have you ever stopped to wonder how those bright, long-lasting finishes on your bicycles, cars and metal goods get there? The almost magical change is because of the application of powder coating (putting metal surfaces in a powdered layer and applying heat to help form one smooth protective finish that leaves an appearance quality which enhances protection only, not rusting or scratches [.].

In this article, we will explore the realm of powder coating further and provide you with a variety of knowledge to help refine your finishing skills in detail - ensuring top-tier results on every project.

How to Do Powder Coating (The Right Way)

The powder coating process is a very detailed procedure that starts with an electrostatically charged powder being applied to a metallic surface. The minor attraction existing between the opposite charges of powder and metal pulls in later consequently keeping higher thickness. The metal is then heated and the powders will melt together to form a continuous, unbroken protective coating.

Powder coating manufacturing process consists of several essential steps. The first happens with proper wipe the surface of dirt, grease and rust. After the surface is clean, powder can be applied with either a spray gun or an application machine specially designed for powder coating. This metal is next baked in an over which causes the powder to melt and fuse with the surface of the component, providing a highly-durable finish that looks good too.

A successful powder coating finish needs knowledge of several techniques; some that are essential include:

Meticulous Surface Cleaning: An important first step is to clean the surface with a solvent-based degreaser (Do not use Acetone) which cleans away any impurities, producing an unblemished finish.

Choosing the Best Powder Coating Machine: It is essential to have good airflow controls and accurate temperature settings in a machine, as that helps you achieve an even finish.

Here are some of this equipment along with a few things to keep in mind while using each: Get an automated powder coating spray gun; Set up your feed rate correct then clean it every day.

Early or Late: Following the powder coat cure times and temperatures is crucial for a successful application, as this ensures that it has an opportunity to bond properly and offers enough time to take root.

The X-Factors For A Successful Powder Coating Finish

Take a look at this article where you will learn hot powder coating tips and tricks

Select Powder Coating: Choose a powder coat type that will enable better adhesion to the substrate based on your choice of material.

Explore Colors of the Spectrum: Discover how mixing colors during curing gives you a beautifully custom end result that mesmerizes the eye.

Uniform results: Just do all of one thing at once and make sure that you apply your powder the same way each time, it should help to reduce blemishes or issues like pinholes/bubbles/craters

Choose a Shine: Customize your finish by opting for either an extra-glossy or flat design depending on the look you desire, glossy finishes add vibrance to colors and matte finishes make textures pop

Starting the Quest for a Perfect and Long-lasting Powder Coating Finish

In the next section, we share a step-by-step list to get that silky smooth powder coating finish - and make it last you a lifetime.

Step 1 Prepare the Surface Clean the surface with a degreaser to remove any residue.

2) Apply the Powder Coating: Use a spray gun or powder coating machine to coat it evenly across all surfaces.

STEP 3 BAKING: Now pop your freshly coated metal into the oven and follow these instructions for the best fusion/durability.

Step IV Cooling and Inspection: Once the metal has been baked, it should be left to cool and then visually inspected for a perfect defect free finish.

Follow these fail-safe steps to step up your powder coating game:

Quality Products Step 1: Take the appropriate used powder coating products to make your final finishing better.

Step 2: Powder Application Precision -Set the Controls on your powder Coating Equipment to be More Precise in Applying a Correct Amount of Powder

Step 3 - Pre-Baking Check: Before you bake the surface, make sure to check your entire piece for defects.

Step 4: Adherence to Baking Instructions- Follow them word for word on the baking times and temperatures as directed.

The reality is that powder coating a wonderful way to develop smooth, long-lasting and protective layers on metal. Take your powdercoat game to the next level by strictly following these steps, good materials and a desire to experiment with colour in order to create stand out finishes. So Remember the best way of achieving a great end result is to be detailed orientated as well allows for some creativity.

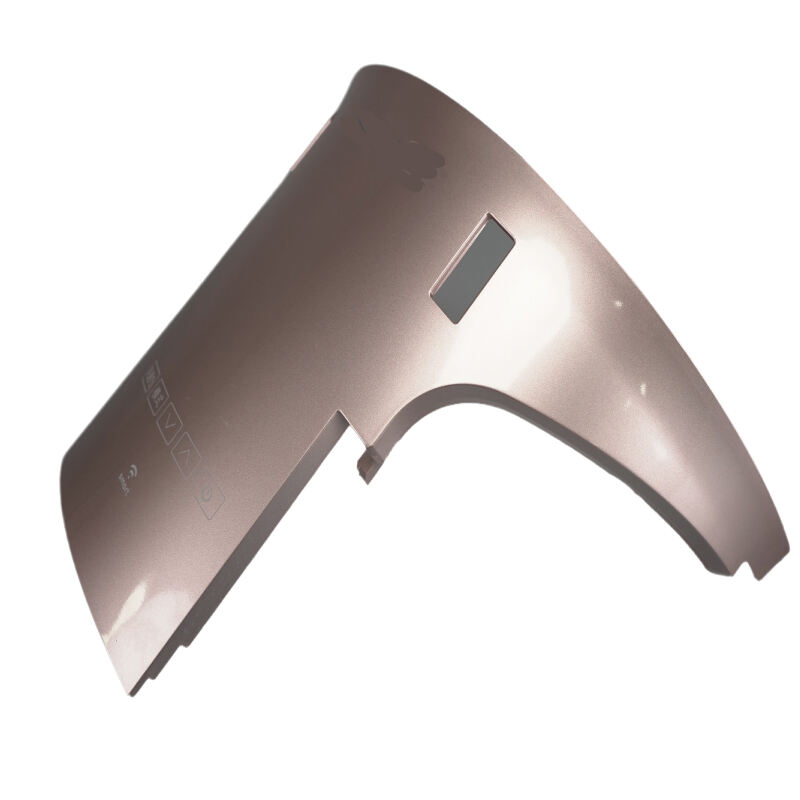

SHQD is equipped with a professional testing lab and 40 QC/QA Inspectors. Quality inspections are conducted from the raw materials, semi-finished items and finished products. Accredited by ISO9001, ISO14001 system, and UL standards We have developed an excellent quality control and finishing powder coating of the environment to ensure that we have a strict control on the pass rate and defect rate. We provide top-quality metal and plastic parts to our clients.

SHQD is a professional RD team, 23 finishing powder coating and design engineers, and over 40 patents related to metal processing of fabrication and injection molding production. We rely on our research and development to contribute to front-end design and to develop innovative technologies, new products prototyping, tests, and marketing. We're committed to providing high-end custom solutions for our customers and their projects.

With 24 years of experience in finishing powder coating, SHQD has become one of the largest injection molding factories in China offering OEM/ODM services for both injection molding production and sheet metal fabrication. We own more than 1,000 production equipment and several production lines that are automated, and offer a one-stop service including tooling design and mold making to production, assembly and logistics.

Our supply chain system is proven and our purchasing team is highly skilled We can lower your cost of finishing powder coating as well as provide injection molding and sheet-metal fabrication services at a competitive price Our sales representatives will assist you to offer high-quality service through a variety of factors such as price quality and transportation