Qingdao Victory Plastics Co.,Ltd.

-

Certified

ISO 9001, UL, SGS

-

24 + Years

EXPERIENCE

-

Location

Qingdao, China

Qingdao Victory Plastics Co.,Ltd.

Certified

ISO 9001, UL, SGS

24 + Years

EXPERIENCE

Location

Qingdao, China

Image by Michael Jagendorf on Pixabay Want to know how so much of what we consume from toys, tools and everything in between is made out of plastic? That process is known as injection mold, and it makes this all possible. So, let's dig more into this amazing method.

The Steps Involve in the Creation of Injection Mold Products- From Design to Production

It all starts with an idea, a big bright happy spark that says i will make something very nice using Injection mold. The images we conjure up in our minds of how we want the end-product to look and behave. With a vision on hand, we head to the next step - create a mold. Think of the mold as a huge brick that is made of metal and its inside has been carved out in one specific design. Now we fill it with melted plastic, let is cool and take the cooled part out. And then, by magic we see our creation so clearly before us!

But, as amazing and versatile the process of injection mold may be - it does have its share of headaches. To help guarantee a smooth production, here are some tips:

Next, make sure the die temperature is proper to prevent any accidents

Different types of plastic spoons produce different results so make sure you choose the right type.

Good Practice for the Injection Molding Process: Building an Ideal Resin

The type of plastic used is important when creating a product with injection mold. We may need it to be strong or flexible depending on our purpose. Based on the plastics properties and end application it can be modified by changing mold temperature, injection pressure,cooling timing etc..

And some have... for mass production, injection mold is quite a common approach but 3D printing gives you different angle of producing plastics. 3D printing starts by imagining a digital design then using a machine to give life. This is best when you are creating a few parts. On the other hand, injection mold would still be a faster and easier choice for high volume production.

Injection mold is a gradually evolutive field due to the efforts lead by innovators as scientists and researchers. Materials that are stronger, more flexible or exhibit other properties and can be developed. Not only this, but the exploration of developments including using robots inside injection mold process can change how we create plastic products moving forward.

To sum it up, injection mold is an interesting process that gives us the ability to create a highly diverse range of products made from plastic. These are the objects that can be made flexible, durable and aesthetic through various ways of creativity design as well as technology. The potential for innovation in plastic part manufacturing is endless as we continue to expand what can be achieved with injected mold. Maybe you will be the next person to innovate into injection mold!

We have a long-standing supply chain and a professional purchasing team which will help you reduce the cost of purchasing raw materials We also provide priced injection mold and sheet metal fabrication Our sales team will help you in providing high-quality services taking into consideration various factors such as cost as well as quality and transportation

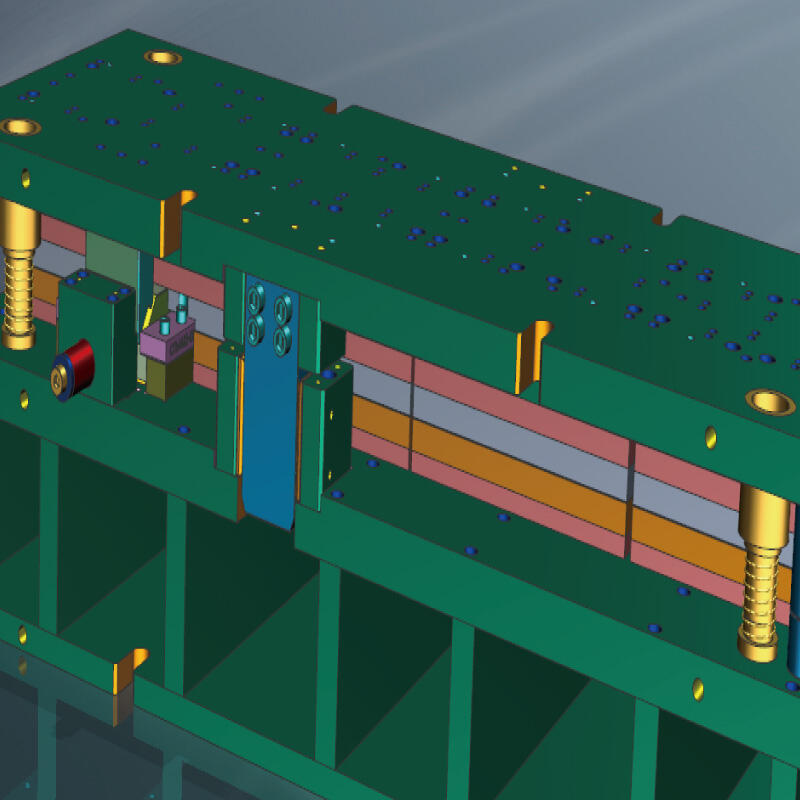

SHQD with injection mold 24 years experience in manufacturing is now one of China's largest injection molding companies. We offer OEM/ODM services for sheet metal fabrication as well as injection molding. We have more than 1,000 production equipment and various automated production lines and offer one-stop solutions from mold design and tooling manufacturing to assembly, production and logistics.

SHQD is equipped with a professional testing lab and 40 QC/QA Inspectors. Quality inspections are conducted from the raw materials, semi-finished items and finished products. Accredited by ISO9001, ISO14001 system, and UL standards We have developed an excellent quality control and injection mold of the environment to ensure that we have a strict control on the pass rate and defect rate. We provide top-quality metal and plastic parts to our clients.

SHQD is a RD company with a professional team comprising 23 engineers and managers. Additionally, it holds more than 40 patents related to metal manufacturing and injection molding. By relying on the power of injection mold, we participate in front-end design and create new technology, new products, prototyping, testing and promotion. We are committed to providing tailored high-end solutions for the projects of our clients.