Qingdao Victory Plastics Co.,Ltd.

Certified

ISO 9001, UL, SGS

24 + Years

EXPERIENCE

Location

Qingdao, China

Workers use machines such as press brakes to bend the metal into necessary shapes. The Press-brakes have a large flat plate which comes down in the metal to cause it first bending into any shape they desire. This is material flexibility, which allows the metal to be shaped into a multitude of different forms (which can include angles, curves and even circles). These machines allow workers to make all sorts of metal shapes for use.

For a variety of other industries that depend upon robust, powerful and even reasons automobiles, massive sheet metal manufacturing is amongst the expertise as they definitely associated with items important for people materials. The list below contains the pieces that are sturdiest because they will hold all of your weight and take lots of pressure. So materials matter and so does the manufacturability with those materials.

An example industry that is known to utilize this fabrication process would be transportation. Visualize all the trucks and buses that we saw on the road. To stay safe and roadworthy, they require loads of special metal parts that are designed especially for them-custom-built frames or engine components. We need large sheet metal fabrication because it would be impossible to build vehicles that are as robust and reliable in our society, without these strong cars.

Mining is another huge sheet metal fabrication industry. Mining machines are large beasts of things and therefore they demand metal parts with all the necessary strength to do their job. The ability of sheet metal fabrication to be so strong and tough makes the heavily machinery used on site, as well as everything that happens below ground possible.

The large sheet metal fabrication world is always evolving as a new idea to people ready try something different and push the limits of what they can produce. They wish to learn how large a structure they can construct or how intricate a part is feasible for them? Innovation is the name of this game.Assertions (Key faculty you must read before giving such interviews.

People are also stretching the boundaries by making robots to' 'print" things. Robots can be written, and then they could produce a metal infrastructure using lots of greater speed in addition to efficiency when compared with an individual. From the health and safety perspective, this quickens output without compromising on quality of work.

Take the One World Trade Center in New York City for instance. A tall spire atop the building underwent large sheet metal fabrication to accompany surrounding steeples. Workers had to match them together just right so this little spire could go on top - and you can see, there is a system of about 100 pieces bolted into place. This demonstrates how precision and artistry combine to create something orchestral.

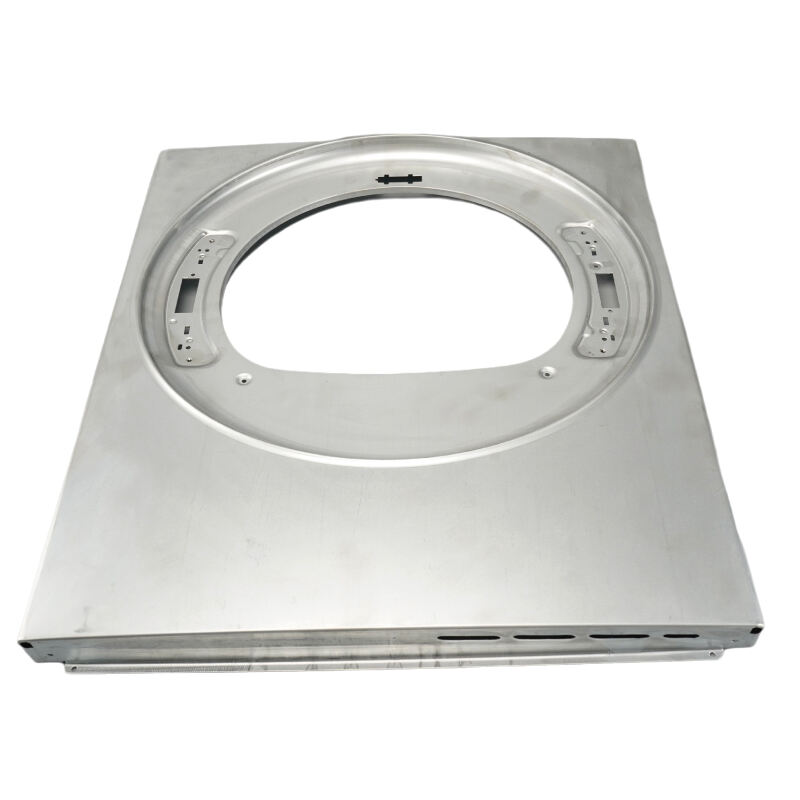

With a total of 24 years experience in the field of manufacturing, SHQD has become one of the biggest injection molding factories in large sheet metal fabrication and offers OEM/ODM service in both injection molding production as well as sheet metal fabrication. SHQD has more than 1,000 production equipment, and several production lines that are automated, as well as a single-stop shop for services ranging from mold design and tooling making to production, assembly, and logistics.

SHQD is a well-equipped testing laboratory with 40 QC/QA inspectors, quality inspection from raw materials to large sheet metal fabrication products and finally finished products. SHQD is certified through the ISO9001 and ISO14001 systems, as well as UL standards. Our perfect quality control system and environmental management system has been designed to manage the amount of defects and also the pass rate. to provide clients with high-quality metal and plastic parts.

SHQD has a skilled RD team, 23 project and design engineers, and over 40 patents related to metal manufacturing and injection molding production. Based on our experience in research and development, we are involved in large sheet metal fabrication and create new technology, new product prototyping, testing, and promotion. We're committed in providing high-end personalized solutions for our clients project.

large sheet metal fabrication supply chain system is seasoned and our purchasing team is professional We can help you reduce the cost of raw materials and offer you injection molding and sheet-metal fabrication at reasonable prices Our sales team can help to provide top-quality services by taking into consideration various aspects including quality cost and transportation