Plastic injection molding is a hugely helpful process for constructing countless numbers of parts of plastic. This is how many companies and businesses manufacture their products. So, what is plastic injection molding and how does it alter the cost of your product? Qingdao Victory will provide a more simple and easy-to-understand answer It is best for 3rd graders to understand, that understanding the following eight major items affecting plastic injection molding costs!

Plastic Injection Molding Explained

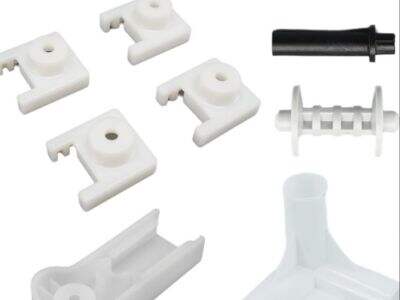

It is simply the process of melting hot plastic, and pressing it into a mold — this particular type being injection molding. This plastic injection mold is a type of shape or container that the plastic takes form when it cools down. After the plastic has cooled, it solidifies into a part that takes on the shape of the mold. This is nice because it will generate detailed and complex shapes pretty easily. This is used in the production of many consumer goods, from toys to car parts.

The material type affects the cost.

When estimating plastic injection molding cost, the first aspect to consider is what type of material will be used. Plastic is a composition of different materials PS: Polifilolicarbamide (Melodacrylite, Vinylpolzetre), which each have their own prices. So there are more expensive plastics, being the higher grade ones or those with specific qualities. Choosing the right plastic for your product can really affect just how much it costs to make. If you use stronger plastic, the product can be further improved — but will also cost more money.

Overall, Price Varies with Design Complexity

The complexity of the design is one of the main factors to consider when designing a plastic product. The cost you would with very ugly and cheap shoes. of creating such expensive as the more elaborate (and difficult-to-manufacture) a design is, Simple designs can be produced by quick-to-manufacture molds, but intricate patterns require specialized armorers that may then result in a better lead time. The higher the complexity of your design, the more time it takes in production and further leads to added cost. Thus, to cost efficiency it is best that the design be minimalistic as much.

Pricing affected by production volume

Plastic Injection Molding — The Quantity of Products you are willing to make another thing that can vary the price of plastic injection molding with a range/number of products it. In general, the more products you make, the lower cost per product. This occurs because the fixed costs- which are constant irrespective of how many you produce become spread amongst plenty items. Thus, the more items you create, the further those fixed costs are divided per unit- result in reducing in cost of production of each item. If, on the other hand you opt to build a huge quantity of products, this will also require more materials and so forth (and thus might change pricing).

The Final Price is Related to Tooling Costs

Calculate Tooling Costs in Plastic Injection Molding Tooling is the manufacturing of plastic molds which form melted plastics. Tooling costs depend on the size and complexity of molds, as well as how many tools you require. Making molds often gets surprisingly expensive, especially if the piece is intricate or produced in numbers. The fact that tooling costs can mount up remarkably quickly makes it a really tricky thing to even guess at when you are trying to figure out what the complete cost of making your product will be.

Finishing and Post Processing Can Alter the Cost

Materials need to be processed and moulded into a specific form, then there may be subsequent steps required in order for the product to become unique. Of course, these additional finishing steps effect the overall costs it takes to make this final product. If the product requires polishing, painting or any surface finishing treatment to make it look good and function as well then price may increase of part. Nevertheless, if you want to opt out of some these extra steps it can help with the cost reduction. In the end you have to do what works for your project and find a balance between quality and cost of those finishing passes.

Testing Steps and the Affect in Price qualities

In the process of plastic injection molding, you need to ensure that your product is high in quality. During production, if anything was to go wrong you would spend a lot to fix it. Quality checkpoints, such as inspection and testing of all the products to ensure that they meet those right standards can be very expensive. The truth of the matter though is that these steps can also help minimize errors and keep customers happier too (as they get a better product). Therefore investing in high quality can save over time by reducing defects and waste.

Cost Depends on Geographical Location

There are various costs to making products around the world. The final price tag on plastic injection molding is highly variable, depending largely on local rules and taxes in other countries, as well as the cost of hiring workers. For example, the price of manufacturing goods might be less in China where there is a variance in tax rates and labor expenses compared to making them at home in the US. It can represent a large part of the overall cost, so companies need to decide where they want them produced.

Which brings us to the bottom line: plastic injection molding is a complex, multifaceted field where many things can vary in order that changes made by tooling are only one part of it. The final price is affected by the type of material, design complexity, volume quantities needed to produce product pieces/tools used in manufacturing and finishing steps. Knowing these statistics will help companies to make the right decisions in order not stagnate production while keeping prices competitive. Qingdao Victory wants to be able to offer such a quality of work but not at the detriment their bottom line.

Table of Contents

- Plastic Injection Molding Explained

- The material type affects the cost.

- Overall, Price Varies with Design Complexity

- Pricing affected by production volume

- The Final Price is Related to Tooling Costs

- Finishing and Post Processing Can Alter the Cost

- Testing Steps and the Affect in Price qualities

- Cost Depends on Geographical Location

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

UR

UR