Welding by Hand and with Robots: The Good, the Bad, and How They Compare

Welding is an important part of several industries like construction and fabrication. The factors involved make it difficult to know whether you should choose between manual and robotic welding. To provide an informed recommendation, it is time to look further into the pros and cons of both methods service against each other.

Advantages of Manual Welding

Using a manual labor to manually weld metal pieces together. It provides flexibility, cost effectiveness and the ability to tackle complicated butterfly welding. Due to the ability of skilled operators, manual welding is easily applied which makes it versatile. In addition, manual welding is often cheaper especially for shorter runs of product as the initial cost to set up a machine will be lower.

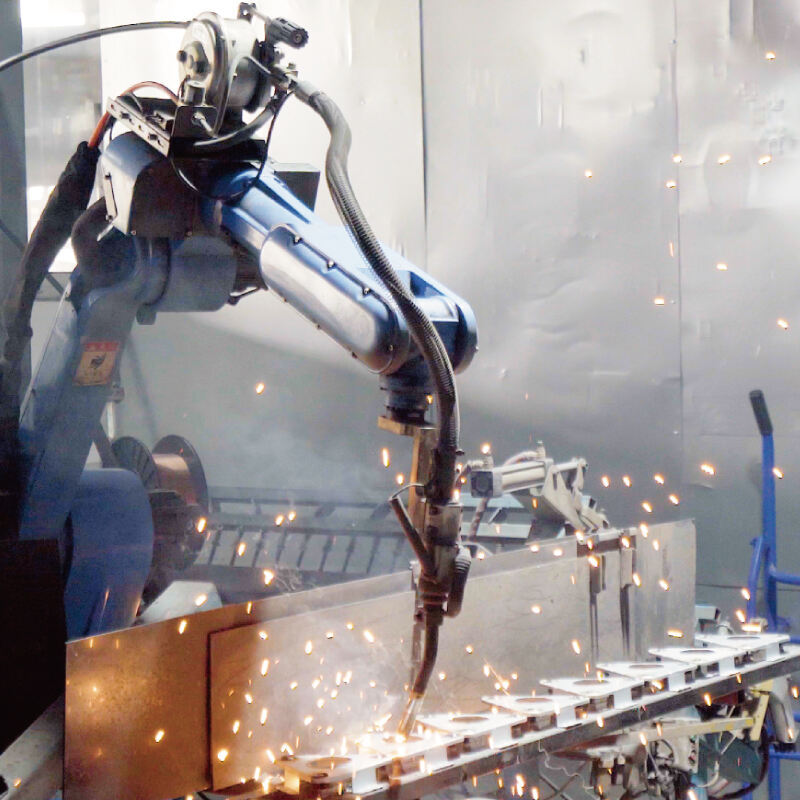

Advantages of Robotic Welding

Robotic Welding is carried out with the help of automatic machines to perform welding. Indeed, perhaps most significant feature of this approach is its accuracy and speed benefit. Automation systems allow robots to do repetitive tasks faster than humans and very precisely, which has the benefit of increased productivity as well as higher product quality. Robotic welding machines by Qingdao Victory also work well in dangerous environments where the safety of humans is a concern, which decreases risks and increases workplace security trough their cnc machining service.

Weaknesses of Manual Welding

Granted, the level of training and expertise that is required in manual welding remains a considerable con. Errors and inaccuracies may be made in the process, which affects end-user experience quality by either lowering it or increasing rework efforts. Maintaining a high standard of quality control particularly when using welding for intricate and complicated tasks like for Plastic Functional Parts. In addition, the process may be hazardous to operators because it involves building up toxic fumes and substances in manual welding that necessitates safety precautions.

Weaknesses of Robotic Welding

Even though robotic welding is the chosen method for many manufacturers, it has some drawbacks one of which is that machines are expensive to buy and maintain in large numbers. The need to train workers in operating robotic welding machines is a specific type of training that can also be costly. Also, robots may not have the versatility needed to perform all welding operations that rely on human judgment ability and decision-making.

Home-Improvement Specific Welding Solution

Determining when to elect manual vs robotic welding will depend upon the strengths of each method and limitations as well. These things are significant when choosing the right one and they include safety, innovation, quality; use and application. With the right welding solution provided by a reputable turnkey automation integrator, it is possible to increase output rates and reduce costs while keeping your operators safe in the work place.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

UR

UR