Hot To Mold: The Highs vs Lows of Injection Molding

Ever wondered how plastic toys, phone cases or parts for your car are made? Follow this deep dive into plastic injection molding to learn all there is about what it is, how it works and see the pros and cons of using an industry wide process.

What is Injection Molding?

Injection molding is one of the most crucial manufacturing processes that includes injecting molten plastic into a mold cavity and solidifying it to result in unique part. Dating as far back as the 1930s, it has grown into the most prevalent method of manufacturing plastic parts because of its speed and reliability.

Benefits of Injection Molding

Complexity and Precision: Injection molding is powerful in its ability to create highly detailed parts with exacting precision. This also makes it a real winner when you need to go into mass production.

Use Case: Injection molding is excellent for large-volume production scenarios, but it might not be the best option when you only need a few parts (low volume) or if these parts are highly personalized and costly molds would be required.

Time: Building a mold can be expensive, as much to thousands of dollars and take several weeks or even months.

You will have to deal with Waste: As the plastic injection moulding service work there is some waste which results in extra plastic that remains inside machine after-cycle, generally thrown away. Adopt an efficient waste management system to prevent harmful consequences on the environment.

Safety:

With respect to safety, one of the most important features about injection moulding machinery is that it semi-automates everything because dangerous hot melted plastic will not come into contact with any other operators in order to minimize exposure.

Usability:

Injection molded products are light weight and easy to handle making them highly desirable for industries like automotive, medical and consumer goods.

Injection Molding Process - How does it work?

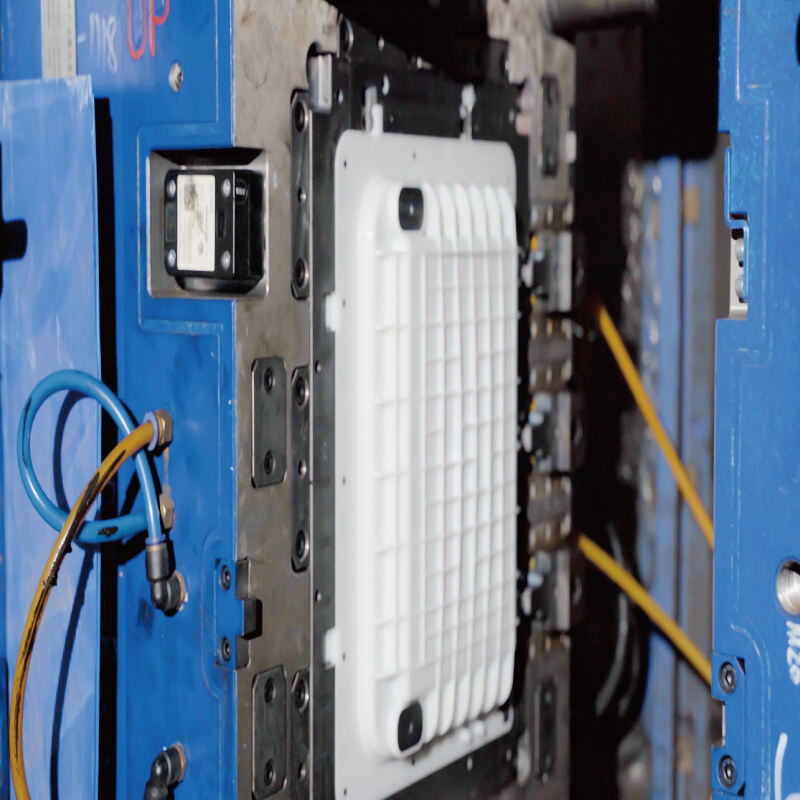

Injection molding starts with the formation of a mold cavity, which determines its eventual profile. One such machine fills the mold with molten plastic that is contained in a specialized melt. After the plastic cures, they open the mold and take out what has been made leaving a cavity which then needs to get filled up again.

Service and Quality Assurance

Companies such as Qingdao Victory, which excel at injection molding specifically, are dedicated to delivering the highest quality in both tooling and production. Its skilled team of experts works in close conjunction with their clients to make sure the outcome meets your every requirement and standard.

In Conclusion

Moulding (such as injection) Molding is a versatile manufacturing process, which can be used to create high quality plastic parts for different industries. Although it is not the most economical way of producing parts in small volumes (custom and even high-volume), plastic injection manufacturing is a preferred choice for mass production runs. Injection molding is a cost-effective and efficient process, which Qingdao Victory can ensure will meet high quality standards with their meticulous approach to customer service.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

UR

UR