Qingdao Victory Plastics Co.,Ltd.

Certified

ISO 9001, UL, SGS

24 + Years

EXPERIENCE

Location

Qingdao, China

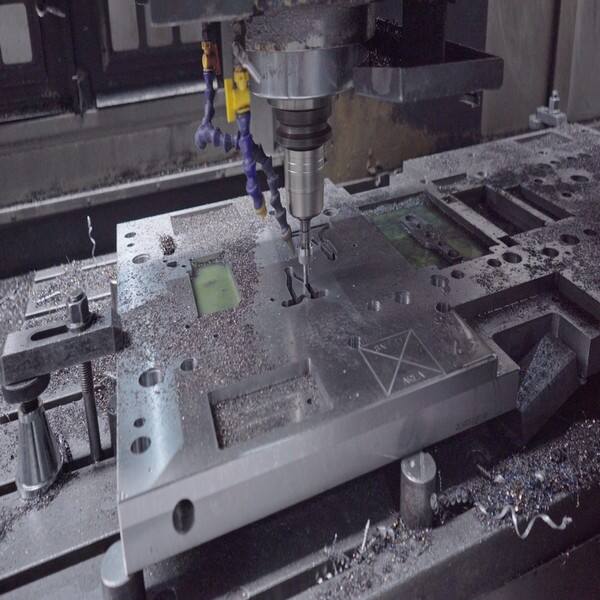

The end goal in this unique world is to make smaller, better parts on a much larger scale, but with even tighter tolerances. What may seem to aid these goals one the most and has become one of the most reliable methods in this method of precision manufacturing is a technique called 4 axis machining. Computer numerical control engineers and manufacturers use it to automate the particular manufacture of complex parts. The enduring beauty of the method as in my reasons is that it allows for making more parts more accurately and with actual precision than anything possible with traditional manual machining. Benefits of using 4 Axis maching are as follows: One of the bigger benefits is all the manufacturing that you will be able to achieve in just a fraction of time as it takes manual methods. Parts are made much faster just because there is a CNC machining running 24 hours 7 days a week. That allows for manufacturers to get parts out quicker which leads to more volume per day and that leads to making more money and producing more. Qingdao Victory custom plastic injection molding - A Few Handy Tips and Tricks By considering what a few handy tips and tricks regarding 4 axis machining you can work more efficiently. Cutting tools will be your most significant consideration. Due to the strength and the possibility to really push them more than 3 axis machining allows. High-speed steel or carbide cutting tools, due to their strength and hardness that the material is going to have to have, are much recommended by expert machinists for such precision manufacturing tasks. Another thing to think about is your numerics, that is, the machine settings. However, the material type/material hardness and the cutting tool itself are significant factors in what you would consider optimum speeds / feeds/depth of cut. Understand these, and you will be able to continuously produce high quality parts

Looking Further into Qingdao Victory custom plastic injection molds The world goes blank now. One of the highlight benefits is how it can fast track manufacturing, especially when compared to traditional manual methods. Because of the 24/7 utilization of a CNC machining, parts can be made at an increased rate and this allows manufacturers to pump out more product do day which is an automatic boost in production all while increasing their overall bottom line

By following some specific tips and tricks, you can make the most of Qingdao Victory custom aluminum parts. One of the most crucial factors to contemplate is choosing cutting tools. Due to their strength and ability to be push further than 3 axis machining allows, high-speed steel (HSS) or Carbide cutting tools are highly recommended by expert machinists for precision manufacturing tasks

Another thing to keep in mind is your numerics - the machine settings. Additionally, material type/material hardness and the specific cutting tool are large factors in what would be considered optimum speeds / feeds/depth of cut. The knowledge of these parameters will help achieve the continuous production of higher quality parts

The 411 on How Manufacturers Prototype Complex Parts with Two Types Of Machining, One Being 4 Axis

4 axis machining is known for its ability to produce detailed and complex parts in a wide selection of industries. With this process, we can easily and precisely convert a 2D part design to the correct 3D model with CAD software. Then, this intricate computer model is sent to a 4 axis CNC machine with advanced software algorithms that can mill the part in highly accuracy

The world of Qingdao Victory custom cut sheet metal is always evolving, with new technologies emerging every few years that promise to deliver even more precision and speed in the production of parts. Notably advances in innovation include multi-axis machines able to make more intricate cuts with higher precision and velocity. The implementation of software bots and AI functionality is another major step taken for the optimization of speed as well other machining parameters dynamically to achieve better part quality during metal cutting

We have a mature supply chain system and an experienced purchasing team which will help you 4 axis machining the cost of raw material purchasing and offer a cost-effective injection molding and sheet metal fabrication services Our sales representatives will assist you provide top-quality services taking into consideration various factors like cost quality and transportation

SHQD is a RD company with a professional team comprising 23 engineers and managers. Additionally, it holds more than 40 patents related to metal manufacturing and injection molding. By relying on the power of 4 axis machining, we participate in front-end design and create new technology, new products, prototyping, testing and promotion. We are committed to providing tailored high-end solutions for the projects of our clients.

With more than 24 years of expertise in the field of manufacturing, SHQD has become one of the largest injection molding factories in China and offers OEM/ODM service for both injection molding production and fabrication of sheet metal. We have more than 1,000 production equipment, as well as several production lines that are automated, and provide one-stop services from 4 axis machining and mold manufacturing to assembly, production, and logistics.

SHQD is a well-equipped testing laboratory and 40 inspectors for quality inspections from raw materials to semi-finished goods to final products. We are certified through the ISO9001 and 4 axis machining systems in addition to UL standards. Our flawless quality control system and environment management system are designed to manage the rate of defects and success rate. to offer clients high-quality plastic and metal parts.