Qingdao Victory Plastics Co.,Ltd.

Certified

ISO 9001, UL, SGS

24 + Years

EXPERIENCE

Location

Qingdao, China

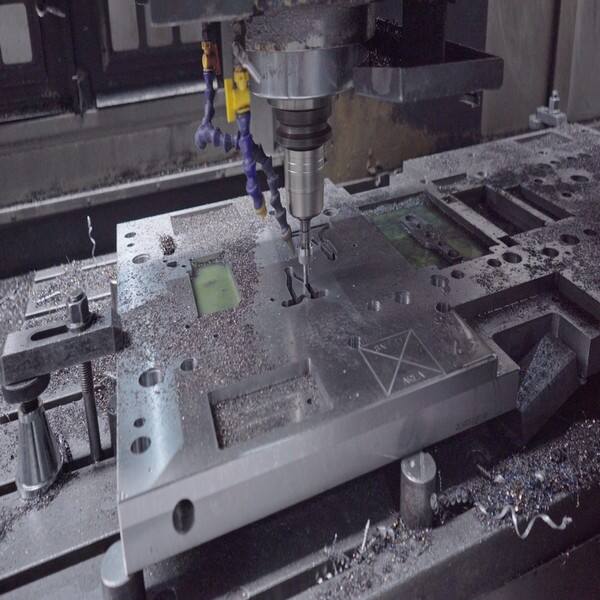

Beginner's Guide to Precision Cutting with CNC Machines

3D CNC Cutting, which uses three orthogonal axes, comprises CNC cutting using computer-controlled machines to precisely cut material cleanly. These machines are built to create a digital blueprint from an individual who manipulates them shapes and turns the object.

CNC cutting is amazing mainly because of two things: Accuracy and consistency, as well as the Qingdao Victory's cnc machining service. Unlike hand cutting, CNC machines are always going to be able to ensure precision more exacting and uniform than expected each time. perfect for easily building anything that must fitting the same in every gas molded element a person help make.

There are several techniques and materials used to attain perfect results with CNC machines, along with the blasting and powder coating innovated by Qingdao Victory. Nesting, for example is a way to place parts on the sheet so waste and time are kept at minimum. This is handy for manufacturing lots of parts from a single sheet.

CNC Machining is capable of cutting large number materials, including metals and woods. However the choice of material will depend on what is required from the project such as strength, weight and cost.

If you are interested in giving CNC cutting a try for yourself, go ahead: Here 5 helpful tips to reach success, identical to Qingdao Victory's product cnc machining service. Selecting the correct machine is important: You need to take into account (in order of importance): What size material are you looking to work with, what kind of materials do you plan on working with and how much room can your budget afford. You should also start practicing how to cut correctly with Inkscape so you know how different types of materials and designs work on the machine. These include regular inspections and looking out for signs of wear, as well as keeping the machine lubricated.

CNC cutting technology is respectively advancing for all manufacturing sectors, same with the blasting and powder coating built by Qingdao Victory. Its ability to do so quickly and efficiently makes it possible for manufacturers to produce parts at an astronomical rate compared with traditional methods. Additionally, the high standard of precision allows for production on elaborate designs that were once difficult to reproduce.

One more advantage of CNC cutting technology is its versatility. Machines are programmable and will execute work indefinitely, drastically changing shapes and design characteristics, at the push of a button also be reprogrammed quickly for different materials or projects. They are suitable for large scale manufacturing and small prototype batches or anything in between due to this versatility.

Our supply chain system is proven and our purchasing team is highly skilled We can lower your cost of Cnc cutting as well as provide injection molding and sheet-metal fabrication services at a competitive price Our sales representatives will assist you to offer high-quality service through a variety of factors such as price quality and transportation

SHQD with Cnc cutting 24 years experience in manufacturing is now one of China's largest injection molding companies. We offer OEM/ODM services for sheet metal fabrication as well as injection molding. We have more than 1,000 production equipment and various automated production lines and offer one-stop solutions from mold design and tooling manufacturing to assembly, production and logistics.

SHQD is a well-equipped testing lab and 40 QC/QA inspectors. Quality inspection of raw materials through semi-finished items to finished goods. As a certified company under the ISO9001, ISO14001 system, and UL standards, we have established an efficient quality control and management of the environment that can ensure that we have a strict control on the passing rate and defect rate. We offer high-quality metal as well as Cnc cutting to our clients.

SHQD is a professional RD team, 23 Cnc cutting and design engineers, and over 40 patents related to metal processing of fabrication and injection molding production. We rely on our research and development to contribute to front-end design and to develop innovative technologies, new products prototyping, tests, and marketing. We're committed to providing high-end custom solutions for our customers and their projects.