Qingdao Victory Plastics Co.,Ltd.

-

Certified

ISO 9001, UL, SGS

-

24 + Years

EXPERIENCE

-

Location

Qingdao, China

Qingdao Victory Plastics Co.,Ltd.

Certified

ISO 9001, UL, SGS

24 + Years

EXPERIENCE

Location

Qingdao, China

The Fascinating World of Plastic Production

I was reading about how a lot of things made by manufacturers get thereAnother thing starting with made in incoming` is from where they are beamed out into the world - or at you. Customized plastic injection molding It's really cool to think about how these simple everyday things are churned out of factories! When you look at all the steps, Qingdao Victory custom injection molding starts to become incredibly interesting how they manufacture these.

Custom plastic injection molds allow manufacturers to produce many parts in a short amount of time and at a low price. They are called Hemoface and this involves making more than a part in one go, so they get lots of other bits with no extra resource. That is the gist of how this works for multiple cookies. While this custom plastic injection molding also helps to minimize wastage as molds can be reused for different components until they meet the last stage of disposal. This Qingdao Victory custom injection mold way can save factories money and be eco-friendly as well.

Consider a chef, baking dozen cakes of cupcake for camping. They then combine it and pour into a cupcake tin to bake many cupcakes at the same time. So custom plastic injection molding is the same, but instead of rhubarb or whipped cream plastic

The first step is to heat the plastic until it becomes a liquid form - similar to melting chocolate for any dessert. This Qingdao Victory custom machining plastic is then poured into a specifically created mold. Once the plastic sets, the mold is opened and you have a new part in your hands. You can repeat this process as many times as necessary in order to produce a considerable volume of the identical objects, much like how batches upon batches of cupcakes are baked by bakers

The strong plastic used is Fiberglass Reinforced Nylon, a through-dyed thermoset material. The sectioned Article That You Want To Be Left Alone With The Bits Of Mold_is painstakingly created with a perfect-fit mold that matches the exact shape and size. Since every dollar bill looks like a dollar from the mint, so too is each part made with this mold identical. So whether you need a part or a thousand, they will all appear and function the same!

It all starts on computers for the invention of a custom plastic injection mold. It starts with designers designing in some software. They create a prototype tool after the design is finished to test how well it works. This is a practice version of what the engineers want to be perfect before they make it all happen. From there, once their prototype is green lit they will produce the final mold that can then start pumping out product for mass production

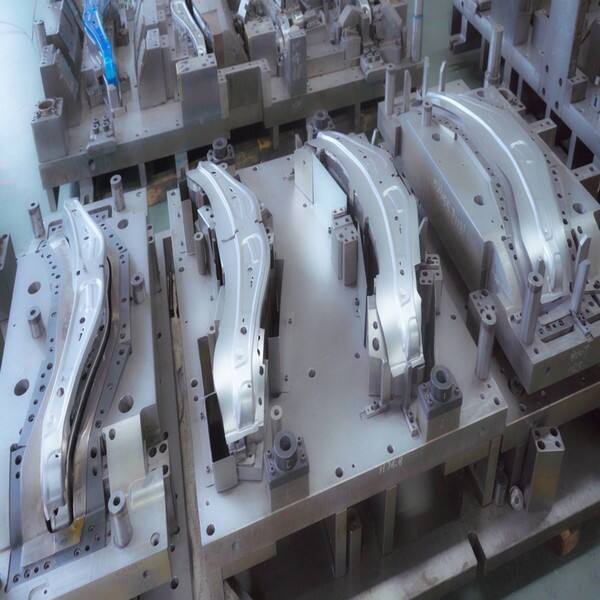

The ultimate mold is cast in Surgical-Grade Stainless Steel. This is chosen because it can endure a lot of use and heat! Each part is cut, cast or drilled using special machines based on a digital approach designed by the computer. Is there an optimization which leaves nothing to chance, even smallest of details are handled precisely?

SHQD with over 24 years experience in manufacturing, has grown to be one of the largest Chinese injection molding companies. We offer custom plastic injection mold services for sheet metal fabrication and injection molding. We have more than 1,000 production equipment and numerous automated production lines and provide one-stop services from tooling design and mold manufacturing to assembly, production, and logistics.

We have a mature supply chain system and an experienced purchasing team that can help you cut down on the custom plastic injection mold of raw material purchasing and offer competitive injection molding and sheet metal fabrication Our sales representatives will assist you in providing high-quality services taking into consideration various factors like cost of transportation quality and cost

SHQD is a RD company with a professional team comprising 23 engineers and managers. Additionally, it holds more than 40 patents related to metal manufacturing and injection molding. By relying on the power of custom plastic injection mold, we participate in front-end design and create new technology, new products, prototyping, testing and promotion. We are committed to providing tailored high-end solutions for the projects of our clients.

SHQD has a highly skilled testing laboratory with 40 inspectors for quality inspections from raw materials to semi-finished items to finished goods. As a certified company under the ISO9001, ISO14001 system, and custom plastic injection mold SHQD has established the perfect quality control system and management of the environment that can strictly control the rate of pass and defect rate. To provide our clients with top-quality metal and plastic parts.

This kind of technology has many benefits for production. It can, for example be applied to manufacture components of medical devices like syringes and IV tubes. It is essential that these parts are clean and sterile so custom plastic injection molding allows for each part to be created with meticulousness

It is also a common application for car body parts. The process results in lighter, easier-to-produce and more cost-effective parts for automakers. This allows for faster production and less wastage of materials when making cars

So, in the end we can say that use of custom plastic injection molding has just changed the way some products are produced and manufactured across all over. It means factories can do thousands or even millions of the same part rapidly, which is really cool. And not just in cans - this innovative technique has greatly impacted a wide range of industries, from medical and automotive to everyday products we know well! The next time you play with a toy, or ride in a car, think about the amazing process that brought these things into existence!