Qingdao Victory Plastics Co.,Ltd.

-

Certified

ISO 9001, UL, SGS

-

24 + Years

EXPERIENCE

-

Location

Qingdao, China

Qingdao Victory Plastics Co.,Ltd.

Certified

ISO 9001, UL, SGS

24 + Years

EXPERIENCE

Location

Qingdao, China

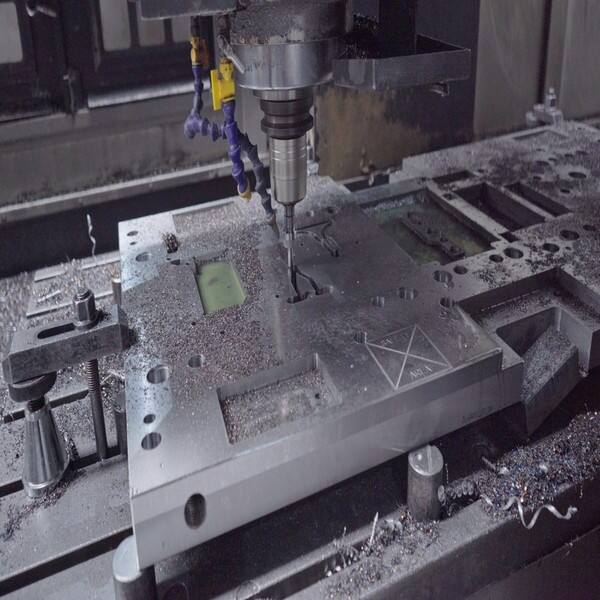

Injection molding Making tool is a special process that allows us to create various shapes and goods from plastic or other materials. It is like a big machine that pushes hot, melted materials into the mold where it can be in final shape and let to harden. After it cools, the material becomes a solid item employed for many purposes in daily life. This injection mold from Qingdao Victory is key in making a lot of the things that we see and use every day. Food containers, toys for children to play with and even car parts that are crucial so they can function; not to mention tools used in medicine that literally save lives!

The mold designer woof with product design also more accuracy in the making of mould for example it can be fitted adequately and hence work on how much close to real responsible all other point action applicable. You need a strong mold, or it will only last two or three restorations. The product also has to be properly manufactured during the injection, which is why production needs upholding of quality standards so opt for custom injection molding from Qingdao Victory.

There are different materials like metal, plastics and rubbers for making molds. Steel: Steel is a great option because it is durable and robust, so they stay strong for long time when the moulds need to be exerted many times. Aluminum is also a commonly used material, particularly in faster low-volume processes. It is lighter than steel and can assist in quicker heat transfer such as some cases. It is important to choose the right materials, since otherwise we might end up with bad products or even breaks in machinery.

There are a few different injection molding factory parts, in factories that use this system to make products. There are the injection molding machine, mold and any other tools or auxiliary equipment that may be needed. Melting the material and then forcing it into a mold is done by an injection molding machine. The machine size and power vary according to the number of products we are interested in producing and also depending on the type of material being used as input so opt for custom plastic injection molds from Qingdao Victory.

Another important aspect of injection molding is the mold itself. For any good designer of mold, the number of parts we need to manufacture is thinking about different factors like what kind of material that will be required for final product and which custom plastic injection molding wilbe there? Molds are made up of a variety of elements which may be manufactured from different materials steel, aluminum, or copper among others. Every material offers a different set of advantages and choosing the appropriate one will determine how well your production flourishes.

Mold-Making technology has significantly improved over the past few years. Emerging methods and materials can help improve the process to be easier, quicker, and more precise. 3D Printing– Innovation in Mold Making Technology This method allows the production of highly detailed parts, with dimension and tolerances beyond compare. By custom plastic injection mold, we can make shapes impossible or difficult to manufacture by traditional methods.

SHQD has a professional RD team of Injection mold making and project engineers, and over 40 patents on metal fabrication processing and injection molding production. Relying on the strength of research and development, we participate in front-end design and develop new technical, new product prototyping, testing, and promotion. We're committed to providing high-end customized solutions to our clients project.

Injection mold making With over 24 years of experience in manufacturing, has grown to be one of China's biggest injection molding companies. They offer OEM/ODM service for sheet metal fabrication and injection molding. SHQD owns more than 1000 production equipment and automated production lines. We provide a complete service that includes tooling design, production, mold making of the assembly line, and logistics.

SHQD has a highly skilled testing laboratory with 40 QC/QA inspectors, quality inspections from raw materials to semi-finished products and finally finished products. SHQD is certified through the Injection mold making and ISO14001 systems in addition to UL standards. Our flawless quality control system and environmental management system is designed to manage the percentage of defect and pass rate. to provide clients with high-quality metal and plastic components.

Our supply chain is proven and our purchasing team is professional We are able to reduce your cost of raw materials as well as provide you with injection molding and Injection mold making for cost-effective prices Our sales team can assist you in providing high-quality services by considering various aspects including cost quality quantity and transport