Qingdao Victory Plastics Co.,Ltd.

Certified

ISO 9001, UL, SGS

24 + Years

EXPERIENCE

Location

Qingdao, China

Fasteners are essential components utilized across various industries, with daily consumption reaching hundreds of billions. In a single car, over 2,000 fasteners are typically used. This article will examine the various processing techniques for these fasteners and the materials associated with each method.

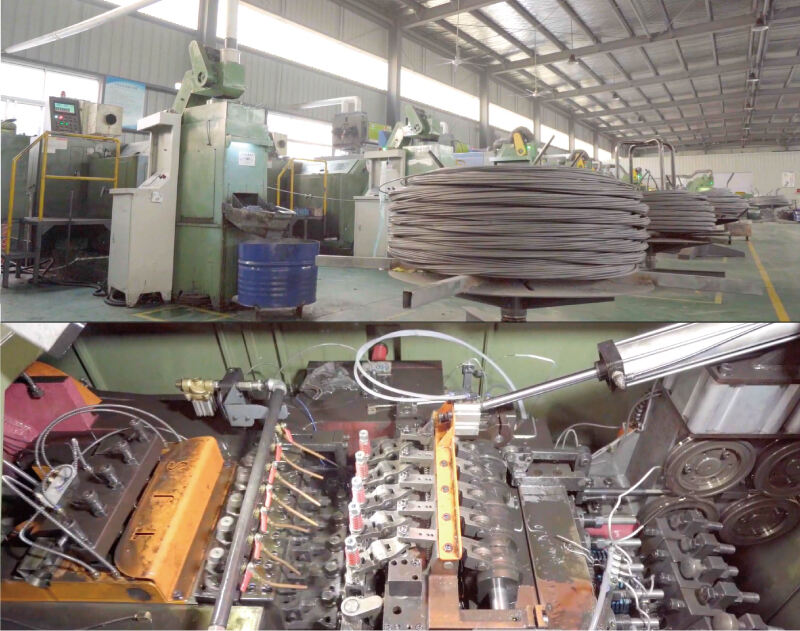

Cold heading is the main processing technique used in our factory for manufacturing fasteners.

This method employs cold-heading machines to create bolts, screws, nuts, rivets, and pins. The production efficiency of cold heading is notably high, averaging 120 pieces per minute, with advanced equipment capable of exceeding 300 pieces per minute. As a result, over 95% of the bolts available in the market are produced using this technique. The process entails the plastic deformation of material at room temperature, transforming round wire into cold heading blanks. These blanks then undergo thread rolling, heat treatment, surface treatment, and other finishing processes to produce the final product. Since the processing occurs at room temperature, materials with superior plasticity are selected.

1. High production efficiency, ideal for large-scale manufacturing.

2. Excellent material utilization, as it typically generates minimal waste.

3. Products exhibit strong metal flow line integrity, mechanical properties, and fatigue resistance, as they do not require further machining.

1. Complex components necessitate multi-station cold heading machines, which can be expensive.

2. The cost of forming molds is relatively high compared to other methods.

3. It is not suitable for processing large or long pieces.

This technique is mainly used for processing bolts and pins through punch presses and hydraulic presses. It has lower production efficiency, and the heating of materials before molding can lead to surface oxidation, resulting in an unattractive appearance for the exposed parts. Therefore, additional machining is often required to meet specifications. The process involves heating the material to high temperatures to soften it, followed by molding in a cavity. Most materials become malleable at elevated temperatures, which eliminates the need for special treatment, provided that the desired mechanical properties are achieved through heat treatment.

1. Capability to process larger and longer pieces.

2. Lower equipment investment requirements.

1. Reduced production efficiency.

2. Results in uneven and unattractive surfaces.

3. Tolerance and burr issues that require further machining.

4. Best suited for simple designs; complex parts necessitate additional processing steps.

This method encompasses turning, milling, drilling, cutting, and other machining techniques, resulting in very low processing efficiency. The materials used in this process must be capable of undergoing heat treatment to achieve the necessary performance.

1. Attainment of optimal dimensional tolerances, making it suitable for components with stringent tolerance requirements.

2. Ability to produce a limited number of custom handmade samples.

1. Extremely low efficiency, making it unsuitable for mass production.

2. High processing costs.

Hot News

Hot News2024-08-13

2024-08-09

2024-07-24

2024-07-17

2024-07-05

2024-07-01